Protecting Critical Infrastructure with Ballistic-Rated Modular Substation Enclosures

Wunderlich-Malec Engineering (WM) leads the industry with innovative engineering design, fabrication and testing of Substation Modular Integrated Control Enclosures (MICE) to meet the electric power grid’s demanding needs.

A recent project demonstrates WM’s capabilities in delivering a UL Level 8 Ballistic Rated enclosure for efficient substation automation and smart grid application.

Background & Customer Needs/Requirements

A major Northeast Utility required a robust substation solution to meet the stringent safety operational demands of the site. The projects design-build requirements included:

- Compliance with UL Level 8 Ballistic standards.

- Integration of IEC 61850 network communications for enhanced interoperability.

- Comprehensive Mechanical, Structural and Electrical Engineering design

- Specification, procurement and integration of all MICE equipment including all protection and control (P&C) relays with intelligent electronic devices (IEDs) required for communication systems.

- Factory acceptance testing of the P&C components and IEC-61850 communication network.

- Seamless re-assembly of the MICE shipping splits at the project substation site.

WM was tasked with designing and delivering a customized solution that addressed these requirements while minimizing downtime and delivering exceptional quality and reliability.

WM ’s Approach & Solutions

1. Expert Engineering and Design:

WM began with a thorough design phase to ensure the MICE met safety, regulatory, and operational standards.

- Detailed Documentation: Developed PE stamped electrical, mechanical, and structural drawings and calculations to ensure adherence to National Electric Code (NEC) codes and State Modular Building Program Codes.

- Collaborative Design Review: Reviewed customer-provided one-lines, three-lines, schematics, and wiring diagrams. WM’s experts provided comments and redlines, recommending design adjustments to enhance constructability and standard compliance.

- Optimized Layouts: Designed cabinet layouts and cable routing plans to maximize efficiency.

- Verified Deliverables: Delivered redlined as-builts of all one-lines, three-lines, schematics, and wiring diagrams upon completion of FAT, ensuring accuracy and compliance with project requirements.

2. Precision Manufacturing and Integration:

With the design phase completed, WM used its expertise and world class resources, including its IEC 9001 2015 Certified Quality System, to fabricate and assemble the modular enclosures.

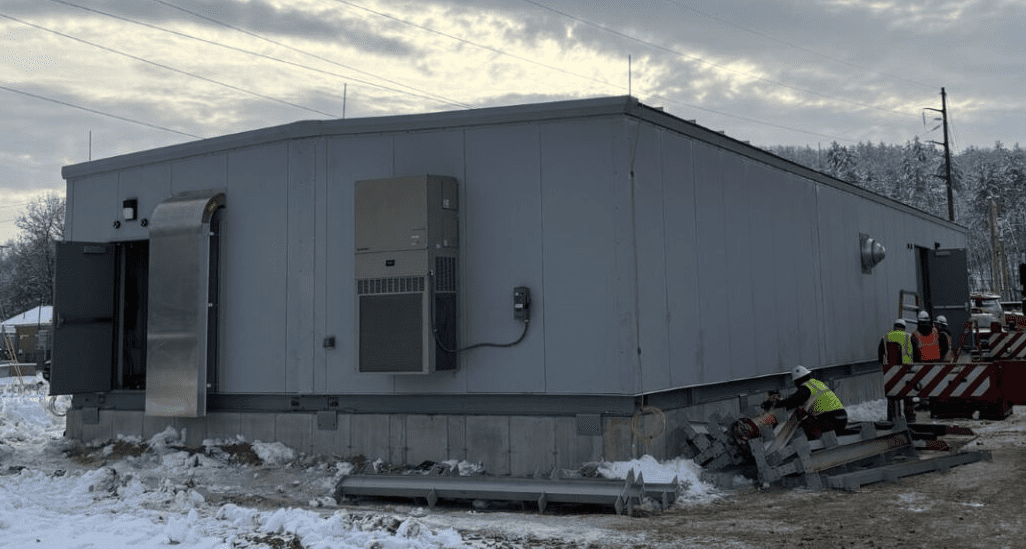

- Ballistic-Rated Construction: Built the MICE in two sub-assemblies, measuring 30 feet wide by 76 feet long , to meet UL Level 8 Ballistic rating.

- Integrated Systems: Incorporated IEC 61850-compliant P&C systems, including primary and secondary cabinets, communications cabinets, Distributed Fault Recorders (DFRs), security systems, and AC/DC distribution equipment. The enclosure also included bathroom facilities to enhance operator convenience.

- Remote Capabilities: Delivered 19 Remote Input/Output (RIO) cabinets for seamless integration with the substation’s existing yard equipment.

- Thorough Testing: Conducted FAT on all components using wiring diagrams, schematics, and one-line drawings, identifying and resolving issues collaboratively with client before final approval.

3. Efficient Delivery and Turnover:

WM ensured a smooth delivery and installation of the MICE system at the customer’s site.

- Pre-Delivery Inspections: A final factory QA inspection was performed, and all project documentation was compiled and sent to customer per WM’s Winslow, ME ISO 9001:2015 certified process.

- Comprehensive Installation: The completed MICE was delivered to the project site, rigged to customer foundation, and fully re-assembled for final project turnover.

Customer Benefits of WM’s Modular Enclosure Solutions:

✓ Faster Deployment: Reduce project schedules with Design-Build Modular Enclosures.

✓ Enhanced Reliability: Improve Quality and Operational Reliability.

✓ Cost Efficiency: Reduce Costs of Project Labor and Shorter Outage Revenue Loss.

✓ Superior Safety: Improve production Safety with Site Ballistic Protection.

Improved Work Environment: Increase employee production in environmental controlled spaces.