Common Mechanical & Electrical Challenges in Industrial Rotating Equipment and How CASE RMC Solves Them

Executive Summary

Steam turbines are critical equipment systems within utilities and large processing plants that meet the growing need of electrical power generation and provide mechanical energy transfer for process operations. Waste heat from exothermic processes may be harnessed for steam production and supply the turbine, with the pressure drops through the turbine supplying lower-pressure steam headers in the facility’s steam network. The turbine not only provides mechanical drive to a pump, compressor, or electrical generator, but it is also the heart of a process plant’s critical systems.

Wunderlich-Malec Engineering’s CASE RMC specialists in turbine control have solved the most complex turbine control challenges for over two decades. They meet the need for dependable turbine operations with turnkey design, build, and commissioning of modern control and protection systems and component assemblies for the precise, safe, and reliable operation of any turbine. One such example is a system implemented on a 15 MW turbine-generator within an integrated phosphate production facility. The project included assemblies and systems covering the range of CASE RMC’s core competencies:

Background & Problem Information

This customer, as with other industrial sites, had an existing turbine-generator with an aged turbine control system, independent of the plant DCS, and with unreliable mechanical and electrical safety systems. To ensure the plant’s continued production and safe rate reductions during frequent power outages, it was essential that the existing turbine-generator provide reliable electric power, especially when islanded from the local electric grid.

Methodology & Approach

CASE RMC expert turbine control engineers collaborated with the client to identify the existing conditions and needs to determine the equipment and systems needed to meet the customer’s expectations. A detailed plan, schedule, and budget were developed and reviewed with the client to ensure a seamless retrofit would achieve compliance with the customer requirements.

The detailed drawings and specifications were produced by CASE RMC, and the equipment was purchased or manufactured at CASE RMC’s modern fabrication facilities in Loveland, Colorado. All systems were simulated and factory tested before delivery for installation at the customer’s site, where installation was completed or supervised by CASE RMC professionals.

All systems were field tested and commissioned before being released to Operations. The client’s personnel were fully trained on all systems and required maintenance, and CASE RMC warranties and services provide continued reliable and safe operation of the turbine-generator systems.

Challenges & Solution

Turbine Control System (TCS)

The existing outdated system was no longer dependable, securing spare parts was becoming an issue, and it did not provide a satisfactory operational interface.

Solution

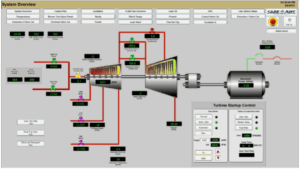

CASE RMC turbine control experts, collaborating with the client, selected the best ultramodern digital controller for the application. They programmed the custom software for the control of turbine speed, generator power, steam header pressures, and turbine overload/bypass flow, as well as turbine auxiliaries that included:

- Redundant processors supporting simplex, dual-redundant, and triple-redundant field devices.

- Fully deterministic software and recursion rates are as fast as 10ms within the Woodward MicroNet Plus’ Real-Time Operating System (RTOS).

- Real-Time Network (RTN; Ethernet, copper, and fiber) communication with remote, distributed I/O in electrical substations and motor control centers (MCCs) to provide the same deterministic and high-speed processing as in the main chassis.

- Ethernet communication (Modbus TCP, etc.) among connected devices and other systems.

- Operator control from custom Human Machine Interfaces (HMIs), the site’s Distributed Control System (DCS), or hardwired panel-mounted interfaces designed for full, backup Operator control in the event of computer failures.

- Complete system programming, testing, and operator training to meet customer expectations.

Turbine Supervisory Systems

Protection from bearing vibration and elevated temperatures is essential to protect the turbine against failure and damage.

Solution

A digital turbine supervisory system was provided and integrated with the turbine protection system to trip the turbine on high differential thermal expansion, rotor position, or vibration.

Turbine Protection / Trip Systems

Compliance with API-670, which is the American Petroleum Institute’s standard that defines minimum requirements for Machinery Protection Systems (MPS), was required. These standards safeguard large, critical industrial equipment (like turbines and compressors) from catastrophic failure by monitoring vibration, speed, rotor position, temperature, and other parameters. They must trigger automatic shutdowns or alarms for issues like turbine overspeed, compressor surge, or excessive vibration, ensuring safety, reliability, and preventing costly downtime. These digital systems use sensors and monitors, requiring fast reaction times (around 100ms or faster). Depending on the specific machinery and application, each system is designed to ensure redundant power and integrated logic for reliable operation in harsh environments.

Solution

CASE RMC engineering experts are specialists in designing and providing mechanical and electrical systems that ensure the unique criteria of each rotating machine follows API-670. The solution design included:

- Independent and diverse tripping for overspeed and other critical turbine parameters, compliant to API-670 (Machinery Protection Systems).

- Custom and redundant electro-hydraulic architecture for reliability, fault tolerance, and integration with hydraulic actuators on the turbine steam valves.

- 100% testable and repairable while the turbine is in operation.

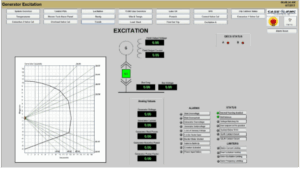

Generator Excitation Systems

To ensure dependable generator operation, a new generator excitation system was required. It must provide reliable field current to the rotor windings of the generator and be designed to ensure reliability, stability, and fast transient response. Also, the remote site, located at the end of a long utility transmission circuit, created challenges beyond standard voltage control. Reactive power (VAr) and power factor (PF) controls were equally important for voltage support, generator, and transformer reliability, and managing PF penalties in utility billing.

Solution

A new state-of-the-art modern digital excitation control system was designed and furnished with a fully redundant architecture for fault-tolerant generator operation. It delivers DC current to the generator’s rotor field windings, creating the magnetic field needed to generate terminal voltage and manage reactive power. The automatic voltage regulators (AVRs) in software and power electronics in the hardware section prevent voltage drops from increased load and enhance power stability. CASE RMC can provide both brushless (using a rotating diode bridge on the generator rotor) or static (using brushes/slip rings) excitation systems in sizes and configurations for any generator application.

Turbine Steam Valve Actuation

Turbine speed and load must be managed by modulating steam valve actuators to precisely control steam flow into the turbine. These highly sophisticated systems convert electronic signals into mechanical motion, requiring high reliability, speed (milliseconds), and precision to maintain steam valve position to keep constant rotation and prevent over-speeding the turbine, as well as secondary control of steam pressures or generator power.

Solution

CASE RMC’s proven experience in providing integrated digital-controlled high-pressure hydraulic actuators was utilized to design, build and deliver an integrated hydraulic solution that ensures safe and efficient operation of the turbine, including:

- High-pressure hydraulic actuators supplying four modulating (control) and two non-modulating (trip / shutdown) valves, fully custom-designed and assembled by CASE RMC.

- Double-acting modulating actuators fully instrumented with dual-coil hydraulic servos and redundant position feedback devices—I/O assignments segregated within the TCS to provide fully redundant and fault-tolerant control such that no single point of failure in the control loop will prevent or adversely affect valve positioning.

- Single-acting, spring return non-modulating actuators designed with test solenoid valves and open/closed/test position feedback switches.

- Nitrogen-charged bladder accumulators, properly sized and placed throughout the hydraulic system to ensure adequate oil volume, aid modulating valve closure in a trip condition.

- CASE RMC also provides steam turbine valve actuation for low-pressure hydraulic systems and electric options to eliminate oil related performance issues, as well as combustion turbine fuel valves.

High Pressure Hydraulic Systems

The client required a new high-pressure hydraulic system to provide highly pressurized fluid to the turbine control and protection systems. This new hydraulic power unit required independent monitoring and control that was integrated within the TCS and the plant’s SCADA control system.

Solution

CASE RMC fabricated a new skid-mounted 150-gallon stainless steel Hydraulic Power Unit (HPU) with secondary containment. The system included:

- Fully redundant main (10 HP / 20 GPM) pumps, filtration and cooling loops, and reservoir heaters.

- The skid-mounted system included a local control panel programmed and integrated with the turbine control system, providing both local and remote automatic control.

Electrical Protection Systems

Unscheduled electrical trips and failures can damage equipment, cause production interruptions and be dangerous to personnel. To ensure the electrical distribution system safely functions, a new protection system was designed and provided that integrated with the site’s existing electrical power systems and the new generator control system.

Solution

A new modern flexible protection system was designed and installed to provide protection schemes that ensure safe electrical operation in the various modes of plant operations including:

- Modern digital protection relays in simplex and redundant tripping architecture for generator breakers, utility tie transformers and breakers, generator bus protection, and feeder breakers.

- Custom designed and manufactured switchgear doors to reduce demo and installation time.

- Flexibility in protection schemes with enhanced personnel training and testing regimes.

Electrical Load Management & Shedding

Energy cost reduction may be a primary challenge in a customer’s requirements. It may be essential that the system design manage energy by shifting usage to off-peak times or reducing consumption during peak periods through Load Shedding. Also, if there is a shortage of electricity supply, or to help prevent the system from becoming overloaded, a critical load management tool is to cut power to non-essential circuits. The system must prevent system collapse or generator overload while ensuring vital systems stay online,

Solution

CASE RMC with Wunderlich-Malec’s electrical power team can provide a system for balancing generation with demand, ensuring system stability and efficient operations. The subject system’s fully custom load-shed control included:

- The system supports isochronous grid-isolated operation for the normally importing electrical power system.

- Real-time monitoring of dynamic electrical loads to automatically shed / trip loads in a flexible priority structure on loss of the grid tie.

- Turbine control software automatically switches to frequency control to keep the islanded facility at rated frequency.

Automation & Control with HMI / SCADA / DCS Integration

Essential to efficient, economical, and safe plant operation was the integration of independent equipment control systems that included Human Machine Interface (HMI), Plant System Control Automation Data Acquisition (SCADA), and the plant’s Distributed Control System (DCS).

Solution

CASE RMC and Wunderlich-Malec engineers are skilled at applying, programming, and integrating a broad range of vendor equipment and software associated with these systems. The team provided:

- All Ethernet devices networked for Operations and Maintenance visibility (Modbus TCP, OPC, etc.).

- Modern interactive local operator control via custom Human Machine Interface (HMI), which includes full engineering software applications and NO license renewals needed.

- Read/write integration with the site’s Distributed Control System (DCS) with graphics replicating those of the local HMI—Control authority restricted or open among the various control locations.

- Integration with the customer’s control and DCS platform, which could include Emerson Ovation, Emerson DeltaV, Siemens, Rockwell PlantPAx, Honeywell Experion, Yokogawa Centum, ABB, Bailey, and other major vendors.

Summary / Conclusion

CASE RMC and Wunderlich-Malec provide full-scope turbine solutions, including core turbine control and protection that encompasses turbine auxiliaries, electrical systems, process controls, and complete integration with balance-of-plant SCADA systems.

Our process knowledge, coupled with our electrical, mechanical, and automation skills, will design and deliver turnkey installation and commissioning projects to provide full scope plant optimization systems. We engineer systems built for longevity, safety, and the lowest cost of ownership. With unmatched versatility and dedicated post-project support, we ensure your operations remain reliable and efficient. Partner with CASE RMC for sustainable, high-performance solutions that power complex industrial facilities into the future.

Ready to upgrade your plant’s performance? Contact us today to discuss your control system needs.

Authored By: Shelby Munds

Email : shelby.munds@wmeng.com