Distributed Control System Assessment and Optimization: Enhancing Process Efficiency for a Global Specialty Chemical Company

Project Understanding:

Global Specialty Chemical company asked Wunderlich-Malec to explore the status/maturity of their current DCS implementations across the North American sites with the intent of identifying and executing improvements on designated sites in the US.

Scope of Work includes:

- Explore the status/maturity of current DCS implementations:

- DCS support such as DCS information extraction, control-loop configuration/re-configuration

- PID tuning

- Historian

- Analyze data and produce a report that includes:

- Control-loop(s) with either (or both) poor setpoint tracking or regulatory control performance that requires further tuning

- Observed instrument/control valve issues

- Alarm Classifications

- Control-loops that are candidates for future APC implementation (MVs).

- The outcome of interviews performed with site personnel.

Outcomes:

Some of the outcomes as identified by the customer:

- Before and after comparison for this particular process T/25 (with 2nd and 3rd additions) batch. In summary (between 2nd and 3rd addition), improvements are:

- Time reduced by 56 minutes.

- Temperature drop reduced by as much as 85 degF.

- Eliminates the need to switch between cool-on and heat-on.

- These are the initial results for 1 product

- New temperature cascade control implemented in process drying.

- Drying time (for the same product) reduced by ~50%

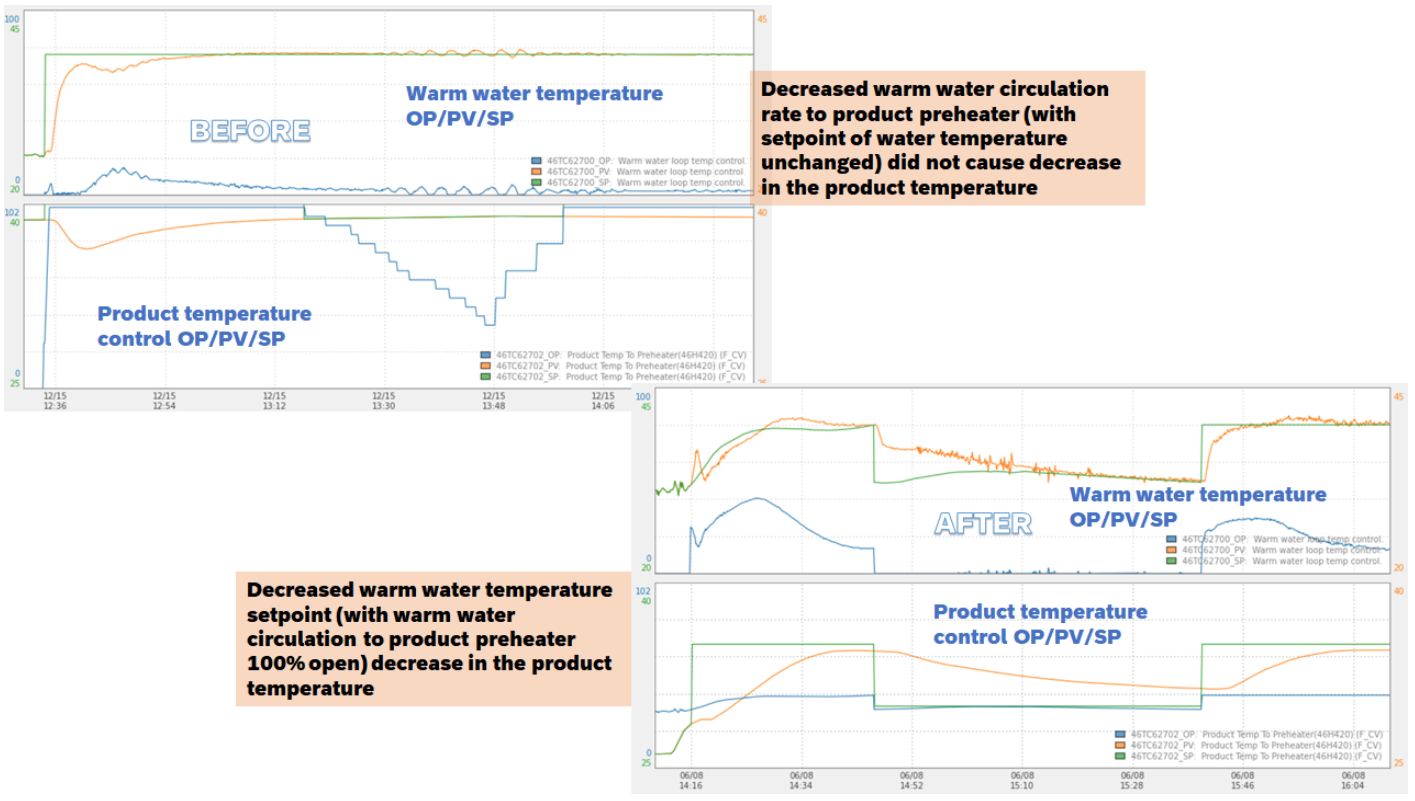

- Other examples: